16 Things About ZIP System® R-Sheathing You Need to Know

5 Min Read November 9, 2023

Since its introduction in 2006, ZIP System’s™ product innovations have strived to streamline and improve the performance of the building envelope. In 2012, Huber Engineered Woods launched ZIP System® R-sheathing, which incorporated a layer of polyisocyanurate (polyiso) foam on the back of a standard ZIP System sheathing panel. Now, in addition to moisture and air management, ZIP System R-sheathing adds thermal performance to the sheathing panel.

Interested in learning more? Below are the most common R-sheathing questions asked and answered:

1. What is ZIP System R-sheathing?

ZIP System R-sheathing is an all-in-one structural panel with built-in exterior insulation. With integrated moisture, air, and thermal protection, ZIP System has improved its game by reimagining traditional wall assemblies.

Altogether, that’s built-in exterior insulation, an integrated water-resistive barrier, a continuous air barrier (when seams are taped with ZIP System™ flashing tape), and structural applications.

2. What Does the “R” in R-sheathing Stand For?

The “R” in R-sheathing stands for R-value. R-value is the measure of a material’s ability to resist heat transfer through the substrate. The higher the R-value number, the greater the insulative properties of the material.

3. Why add exterior continuous insulation to a wall assembly?

Continuous insulation increases energy efficiency. Unlike cavity insulation, wood and metal framing have low R-values. As a result, heat can be lost through the framing members, known as ‘thermal bridging.’ Continuous insulation can reduce the heat energy lost through thermal bridging by separating the conductive framing members from the exterior environment.

Keep energy and heat loss to a minimum with ZIP System R-sheathing.

4. How is installation different from ZIP System sheathing?

Since ZIP System R-sheathing has added thickness due to the foam, longer fasteners are required to install the panels. Otherwise, the installation methods are quite similar. The panels are fastened foam side to the framing, and the panel seams are addressed with a ZIP System seam sealing product such as ZIP System™ flashing tape.

For more detailed information, check out the available R-sheathing installation videos and installation manual.

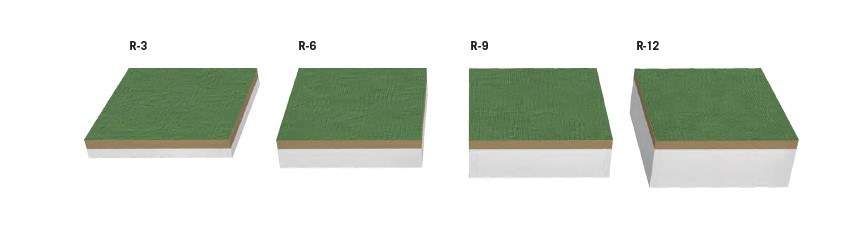

5. Does ZIP System R-Sheathing vary in thickness and length?

ZIP System R-sheathing panels come in different sizes, thicknesses, and R-values. Check out the ZIP System R-sheathing product page for more detailed information.

6. Is ZIP System R-Sheathing only suitable for cold climates?

Not necessarily. The benefits of R-sheathing are more significant in colder climates in comparison to warmer or moderate temperatures. However, because R-sheathing helps to reduce heat transfer through thermal bridging, its benefits can be seen in most climate zones.

7. Does R-sheathing help satisfy 2021 IECC requirements?

Yes. Due to thermal requirements in the 2021 International Energy Conservation Code (IECC), more of the U.S. (United States) will be required to use exterior insulation, and ZIP System R-sheathing helps to satisfy these updated code requirements.

For more information check out the full report or contact our technical team.

8. Can spray foam insulation be used with ZIP System R-sheathing?

Yes. Using open-cell (low-density) spray foam and closed-cell (medium or high-density) spray foam is a popular insulation option for the wall cavity. Both open-cell and closed-cell spray foam will bond to the back of the ZIP System R-sheathing panel as long as environmental factors permit the application of spray foam insulation.

9. Can additional continuous insulation be added to ZIP System R-sheathing?

No. The polyiso foam of the ZIP System R-sheathing panel has low vapor permeability, and adding additional impermeable insulation such as XPS, EPS, or polyiso foam will create a vapor barrier sandwich around the sheathing panel.

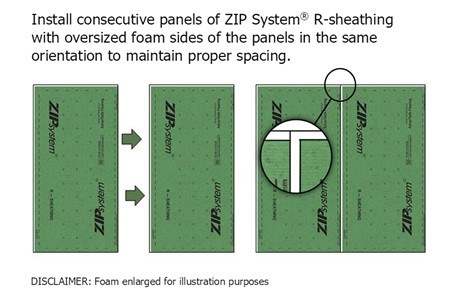

10. Does ZIP System R-Sheathing need to be spaced?

Like standard ZIP System sheathing, the wood portion of ZIP System R-sheathing panels need to be spaced to allow for expansion and contraction. However, ZIP System R-sheathing makes the process easier. The foam portion of a ZIP System R-sheathing panel is oversized on one 4’ edge and one 8’ edge to provide the proper spacing. By oversizing the foam panel, the installation of R-sheathing allows a continuous plane of insulation while still offering the appropriate ⅛” gap between the wood panels.

11. Can ZIP System R-sheathing be installed on a roof?

Although continuous insulation may be desired for specific roof assemblies, ZIP System R-sheathing is recognized and warranted only as a wall sheathing panel. Any use of ZIP System R-sheathing on a roof should be detailed by an architect or design professional.

12. Can ZIP System R-sheathing be installed over metal framing?

ZIP System R-sheathing can be installed over light-gauge metal framing, but there are limitations to this application. When installed over metal framing, R-sheathing does not contribute to the lateral resistance of the wall assembly. In addition, R-sheathing cannot be utilized in fire-rated assemblies when installed over metal framing. For more information regarding R-sheathing installation over metal framing, including fastener information, check out this tech tip.

13. Can R-sheathing be installed on a masonry or concrete wall?

Yes. If you’d like to overlap your foundation or continue your siding or exterior cladding below the wood-framed wall, R-sheathing can be fastened to concrete or masonry walls. For more information check out this tech tip.

14. Can R-sheathing be used in fire-rated assemblies?

Yes. ZIP System R-sheathing can be used in proprietary assemblies we have tested, which can be found here.

15. Can R-sheathing be used in seismic zone C+D?

Yes. ZIP System R-sheathing can be used in seismic zones C and D. It must be designed in accordance with the documents listed below, with the ultimate shear capacity instead of the allowable.

16. Where can I find ZIP System R-sheathing?

Check with a local distributor or buying source, or contact a local Huber Engineered Woods representative to learn more.